Engineerd for Demanding Applications

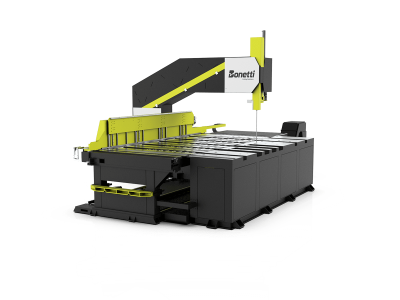

At Precision Saws, Inc., we supply band saw machines built to handle the exacting requirements of industrial metal processing. That’s why we work with Bonetti—an industry leader known for delivering band saw machines built to handle high-speed production, repeatable tolerances, and non-stop operation.

Since 1979, Bonetti has specialized in designing and manufacturing high-performance band saw machines for metal processing. These machines aren’t retrofitted or adapted—they’re engineered from the start to deliver clean cuts, long blade life, and consistent part quality in aluminum, copper, bronze, and other non-ferrous materials.

Bonetti’s technology is designed to reduce scrap, accelerate cycle times, and simplify operations. For fabricators, extruders, and contract manufacturers, these band saw machines offer more than just cutting—they solve the performance issues legacy equipment can’t keep up with.

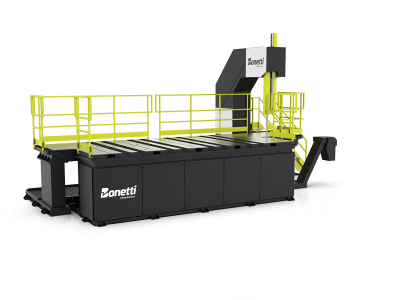

Production-Ready Band Saw Machines

Bonetti’s band saw machines are tailored for continuous use and engineered to deliver stability across shift changes and material types. Every model minimizes manual steps while supporting fast changeovers and reliable throughput. Engineered advantages include:

- Rigid blade tracking and secure material clamping

- Automated alignment to reduce setup variation

- Simple control interfaces to shorten training time

- Specialized designs for aluminum and red metal processing

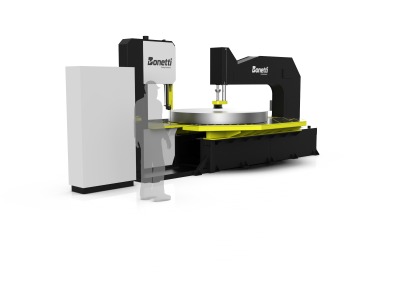

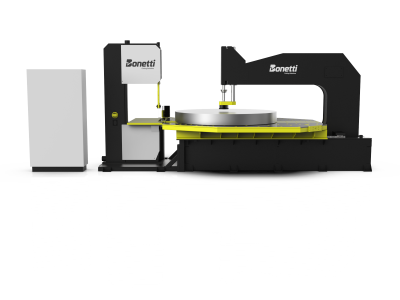

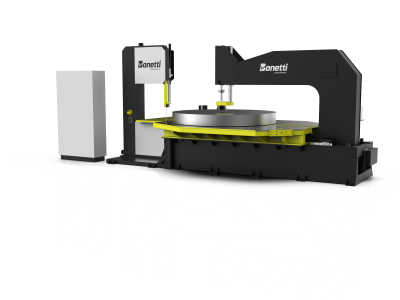

Four Specialized Series. Built Around the Application.

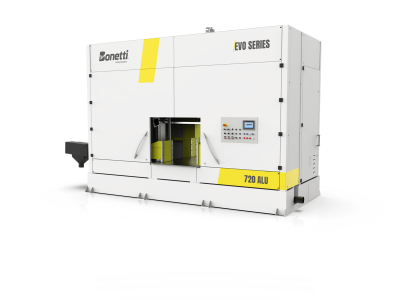

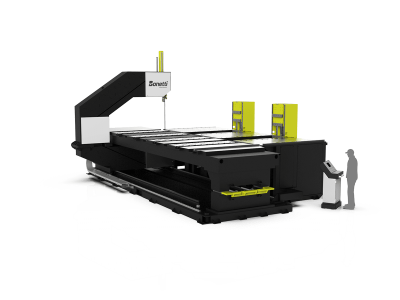

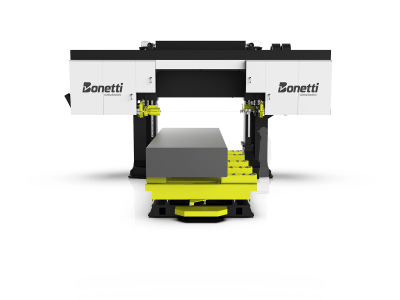

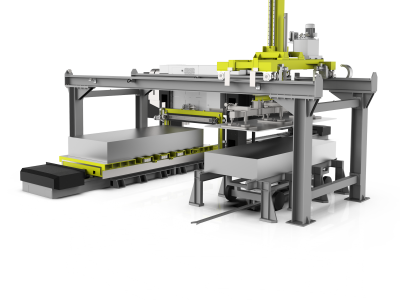

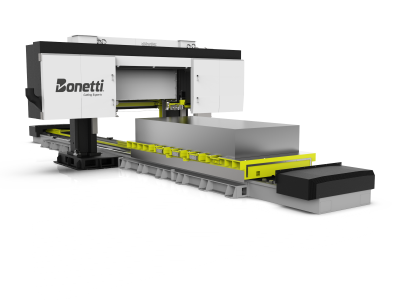

EVO Series - Automatic Bar Sawing

A horizontal bar saw developed through 40 years of focused design. EVO delivers fast, stable cuts across long production runs, with minimized scrap and tight dimensional control. Ideal for aluminum and red metal bar stock.

More information:

www.bonettigroup.eu EVO SERIES